Case

Amazon Data center ventilation System Engineering in Japan

At the end of 2020, Foshan Tanghan Precision Metal Products CO., Ltd. and J. CREATE CO., LTD of Japan agreed on a ventilation system engineering project for Amazon's data center in Japan. Foshan Tang Han is responsible for the design and production of the ventilation system. The project market has grown for 14 months, and the total capital scale is about 34 million RMB.

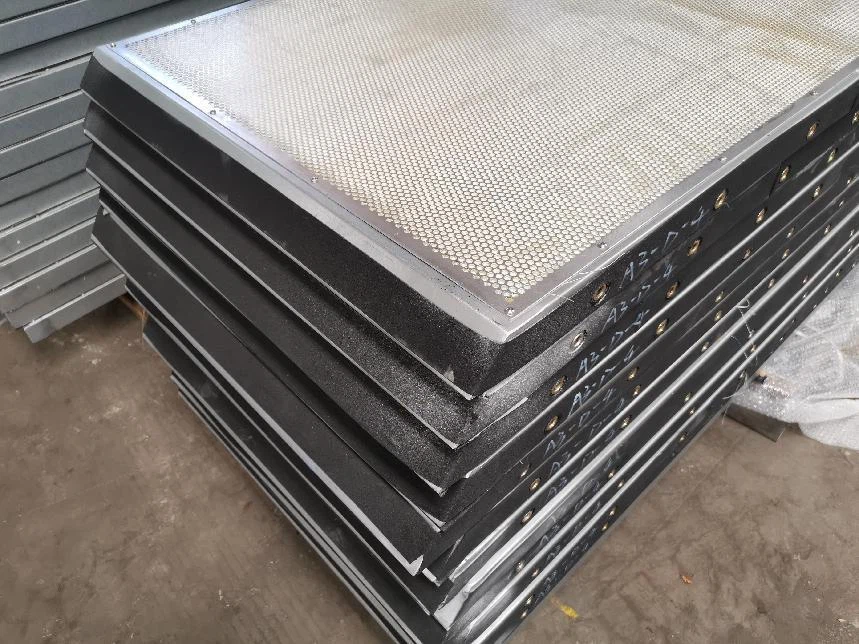

Through the continuous efforts of Tanghan Engineering Department, the Japanese J · CREATE CO., LTD finally confirmed the modular production and installation design concept of our design, that is, the large ventilation duct is connected by stainless steel screws and sealing rubber strips, so as to facilitate transportation, assembly, and leakage prevention effect.

In terms of material selection, our engineers selected Magnesium aluminum zinc plated plate imported from Japan. Compared with traditional galvanized plates, this material has a zinc content of up to 275G/m2, which has high stability of rust prevention, corrosion prevention, waterproof and sunscreen. At the same time, the broken interface has the effect of automatic repair, and will not rust in the section even after cutting and stamping. Through laser cutting, CNC bending, opening, sheet metal production process, and then use high-density attractive fire insulation glass wool as the sandwich filling, so that the heat insulation, waterproof, rust effect of the whole product can be greatly improved.

After the early cutting, then is the number of punching, riveting, and then hoisting, all the screw accessories are made of 304 stainless steel, all the installation Angle code, the bracket is the material magnesium aluminum zinc plated plate or hot dip zinc surface treatment, to prevent the product in the future use of the process of oxidation or rust.

Through this modular design, we saved about 42% of the transportation cost and 37% of the labor cost for Japan. Finally, the project was shipped directly to Tokyo Port of Japan through containers. After later installation and debugging, the project was successfully accepted. The Japanese side was very satisfied with this and continued to expand cooperation with our company. Our strength and confidence in participating in international engineering projects have also been greatly improved.