Basic Introduction Of Sheet Metal Processing

Jul 27, 2020

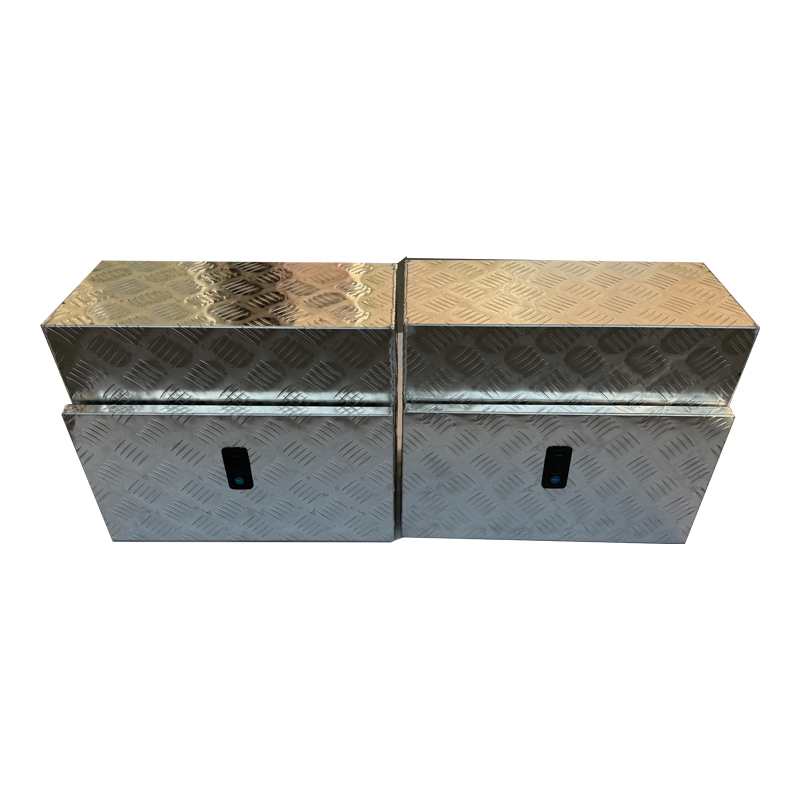

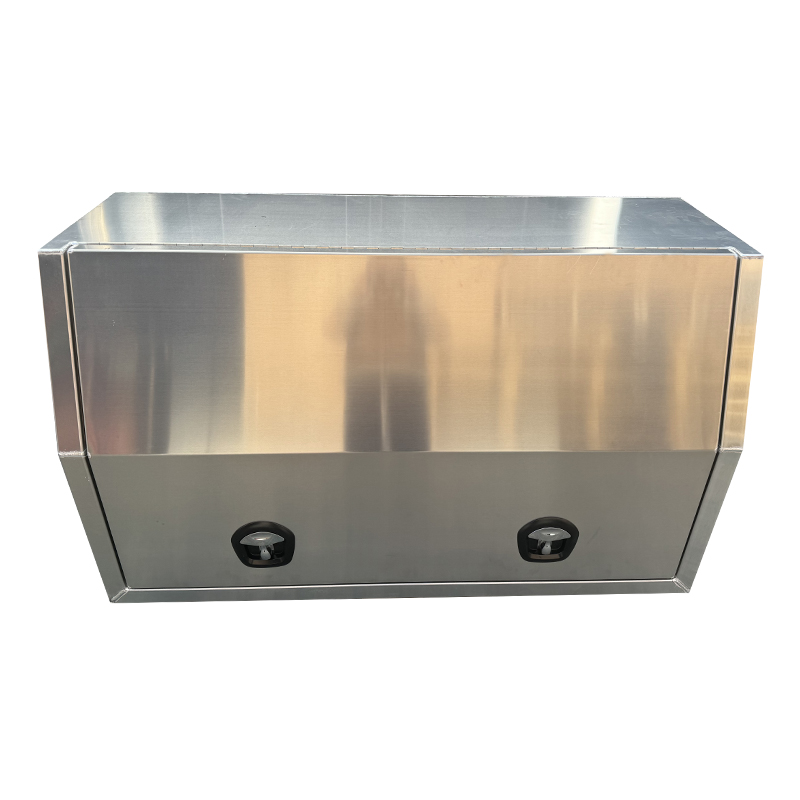

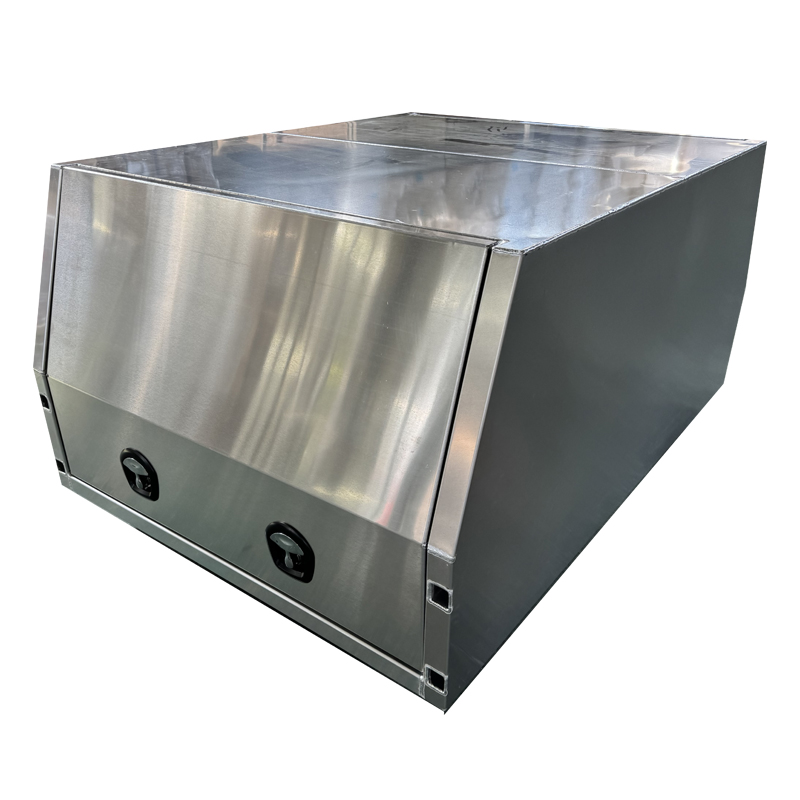

Sheet metal processing is a hub technology that sheet metal technicians need to grasp, and it is also an important process for sheet metal product forming. Sheet metal processing includes traditional cutting, blanking, bending and forming methods and process parameters, as well as various cold stamping die structure and process parameters, various equipment working principles and operating methods, and new stamping technology And new technology. Part metal sheet processing is called sheet metal processing.

Specifically, for example, the use of plates to make chimneys, iron barrels, fuel tanks, oil tanks, ventilation pipes, elbows and small heads, sky circles, funnels, etc. The main processes include shearing, bending, bending, forming, welding, riveting, etc. Certain geometric knowledge. Sheet metal parts are thin metal parts, which are parts that can be processed by stamping, bending, stretching and other means. A general definition is a part with a constant thickness during processing. Corresponding to castings, forgings, machining parts, etc.