What Are The Commonly Used Sheet Metal Processing Techniques?

Aug 04, 2020

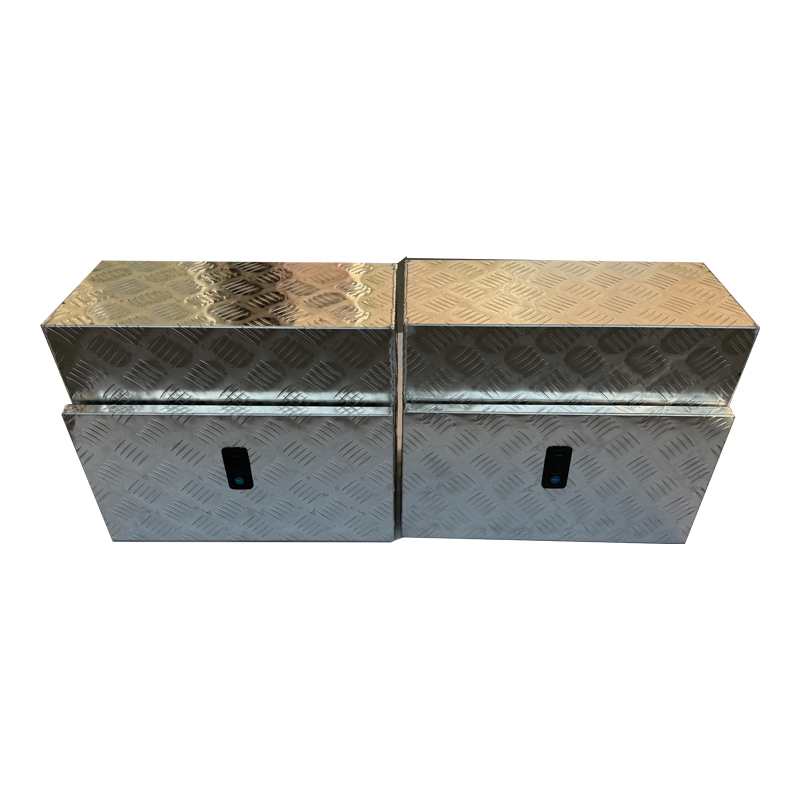

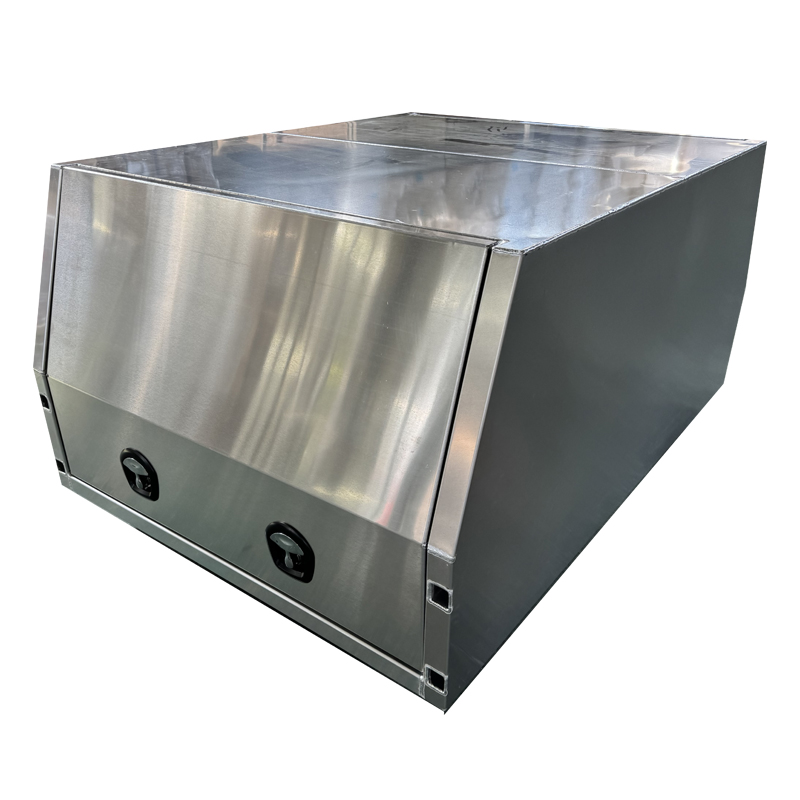

With the continuous development of industrial technology, especially mold and numerical control technology. More and more parts made of thin-walled plates have begun to use sheet metal processing, which not only improves the overall rigidity and aesthetics of the parts, but also improves the processing efficiency.

Sheet metal processing, as the name implies, is the process of processing metal sheets, which mainly refer to thin-walled sheets. For parts made of sheet metal that are too thick, with the current level of production technology, it is not possible to perform sheet metal processing on them in mass production.

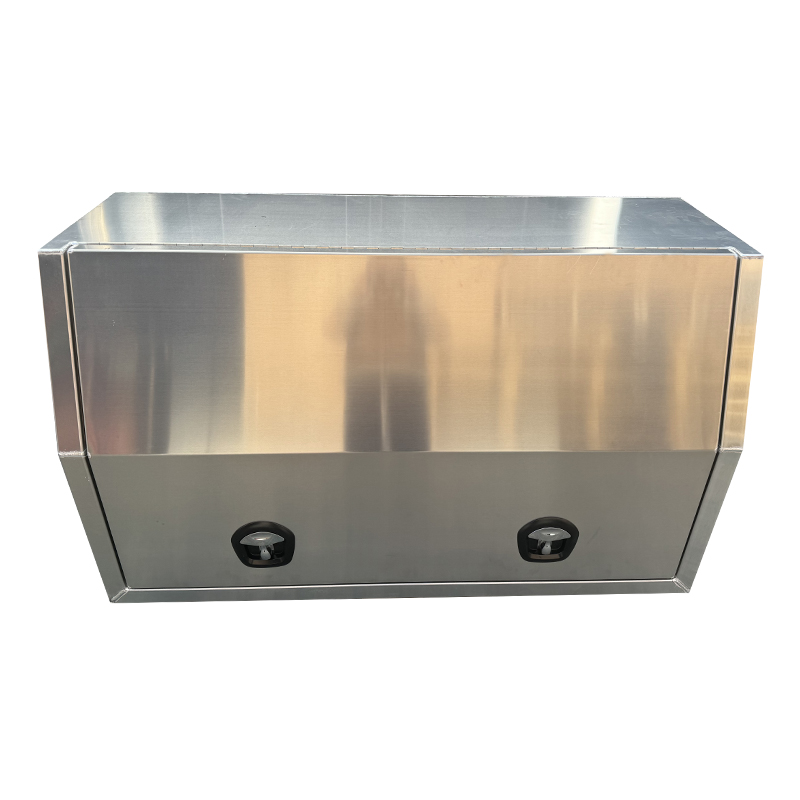

Here are a few commonly used processes for sheet metal processing. The first process in sheet metal processing should be blanking. In large-scale industrial production, the cutting methods of sheet metal materials are mainly cut by punches and shears. Various high-energy beams can also be used to cut the materials. For example, lasers, electron beams, and ion beams can be used to cut sheets. The cut is neat and beautiful. The combination of laser, etc. and numerical control technology can easily realize automation and is highly efficient.

When the blanking is completed, the sheet metal processing enters the second process, that is, forming, which mainly includes stretching and bending, which requires the use of corresponding stretching dies and bending dies. Stretching is generally performed on ordinary punching machines and CNC punching machines. The bending process needs to be performed on the bending machine or the CNC bending machine. In modern industrial production, CNC bending machines are mainly used, and manual bending machines are mostly used in single-piece, small-scale trial production.