How do I choose a good tool box?

Jun 28, 2021

The toolbox is a container that can store different tools or equipment. It may be a small portable box like Stanley hand box or a large storage container with casters like job site box. Modern toolboxes are mainly made of metal or plastic. Before the 19th century, wood was the core material of choice for toolboxes.

Small portable toolboxes are sometimes called hand box or portable toolboxes. Most portable toolboxes have a handle on the top and a hinge to make the lid easy to open. A plastic toolbox with tools may weigh the same as an empty metal toolbox. Metal toolboxes may rust if used for too long or lack of maintenance, and sharp edges may hit something and leave marks. However, metal is stronger and safer than plastic, while plastic toolboxes are lighter in weight and economical, but the safety factor is relatively low. Therefore, we need to balance its durability advantages and weight disadvantages, and choose a suitable one according to our demand.

So what kind of tool box is the best? Is the price the lowest? Is it beautiful in appearance? Or the most durable?

In fact, the toolbox that suits you is the best!

Firstly, filter according to your own needs, and select a toolbox that is suitable for your truck storage tools, so that you can find tools when you need it; then choose the material of the toolbox, usually three different materials: aluminum, iron, and stainless steel Different materials will be subdivided by thickness; then look at the performance of the toolbox, whether it has waterproof, sun protection, load-bearing capacity, assembly location, space utilization, color matching, surface treatment and many other factors.

According to market demand, our company has produced the following toolboxes:

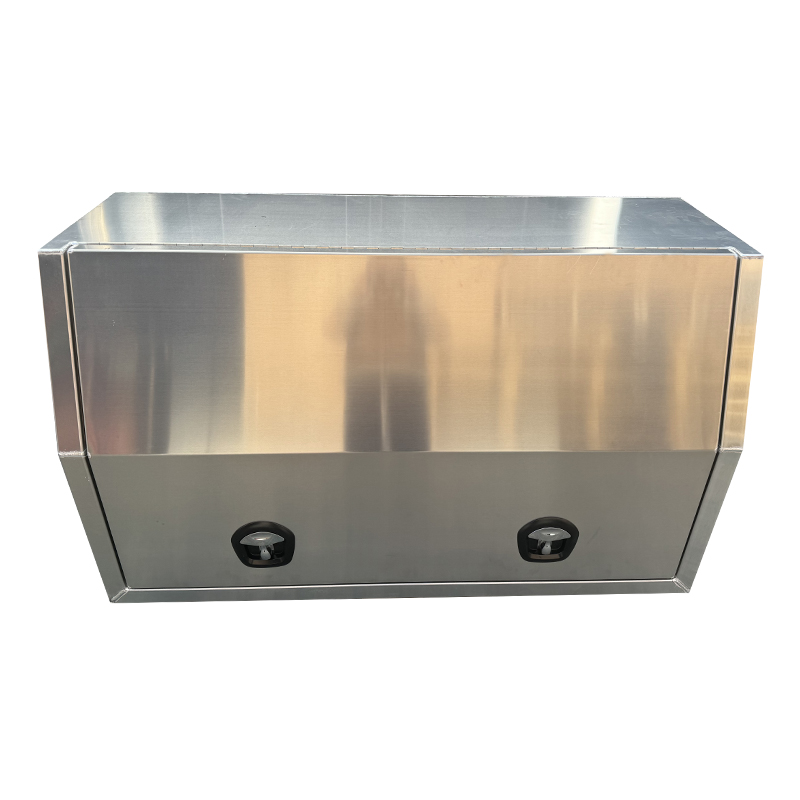

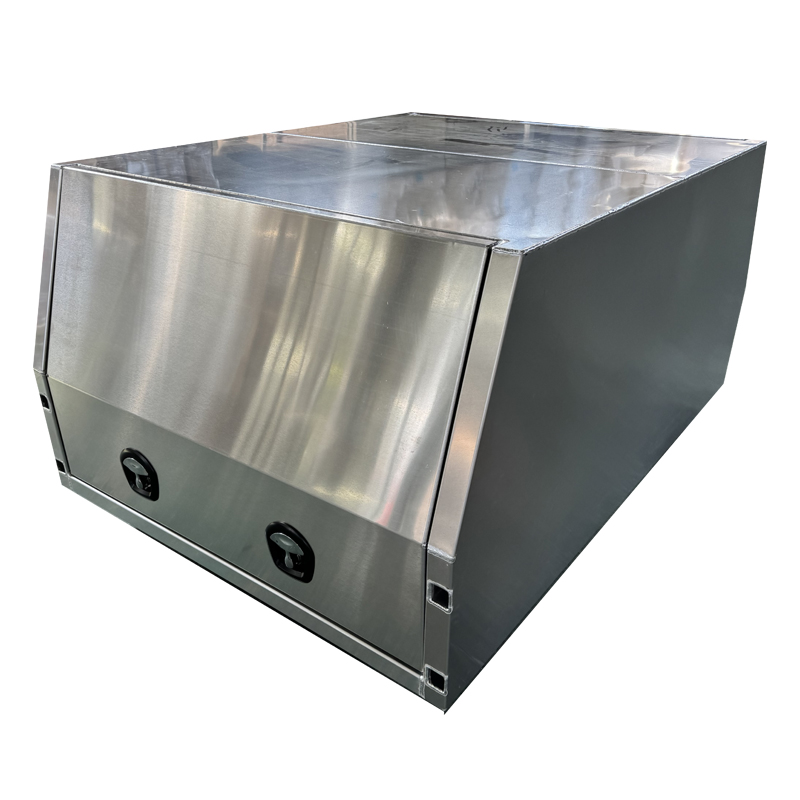

1、Flat alloy tool box

The main material is aluminum flat alloy plate, with stainless steel and mild steel as auxiliary materials, and heavy slide rails, stainless steel T locks and piano hinges, gas struts support, waterproof rubber and other accessories are added, and the surface is made according to customer requirements The handling makes the toolbox beautiful and generous, strong and durable, and it is very practical in the field of tool storage, small driving transportation and outdoor camping.

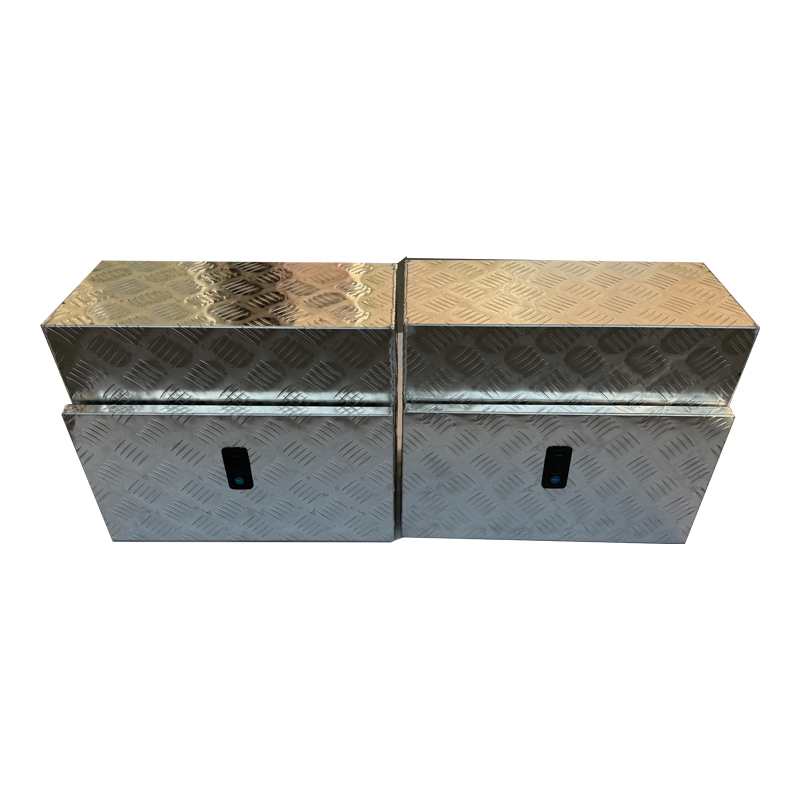

2、Aluminum checker plate tool box

The aluminum checker plate is rolled by a roller press to form a convex pattern on the surface of the aluminum flat plate. There are many types of checker plates, the most common is the 5 bars aluminum checker plate (shaped like a willow leaf). This type of checkered plate goes to the Australian market More common; the other is called diamond checker (pointer checker), this kind of checker goes to the US and Canadian markets more. Customers can either choose additional surface treatment or use it directly.

3、Iron tool box

The use of high-quality mild steel or stainless steel plate for laser cutting, counting punching, bending, welding and other processes makes the whole box strong and durable. This kind of toolbox is more used on trucks because of its large storage space, high safety factor and economical price, but it is usually relatively heavy.

4、Plastic tool box

This toolbox is made of high-density PE material, with reasonable structure design, thick materials, high strength and toughness, anti-static, complete color specifications, light weight, large storage space, suitable for many models, beautiful and fashionable And other advantages; generally used to store hardware tools on pickup trucks.

In addition, in order to meet the needs of more customers, we will also customize materials, styles, colors, etc. according to customer requirements, making the toolbox more complete; we also have OEM/ODM services for you to choose. You are always welcome to contact us, and we will provide you with a suitable solution!